-

Dowell Materials > What is Phenolic?

Phenolic Moulding Compound (PF) is also commonly known as "Bakelite". It is favorably used for various used due to the excellent heat resistant and dimentional stability.

- Engineering Plastic can be categorized into two kinds of resin: Thermosetting resin and Thermoplastic resin. Phenolic Moulding Compound is thermosetting resin.

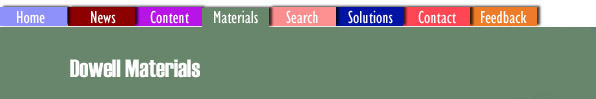

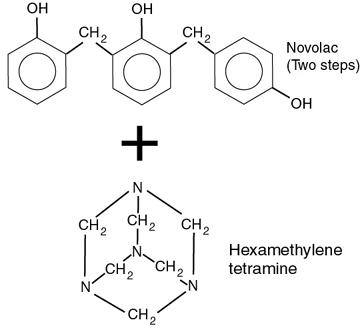

There are two types of phenolic resin - Novolac and Resol. Where Novolac is two stage compound. And Resol is one stage compound.

- General specifications of Phenolic Molding Compound

- Novolac (Two Stage)

The above two stage process generates three-dimensional reticulated structure and Ammonia Gas (NH3) after injection or compression process.

- Example of Novolac (two stage) phenolic molding compound are General Purpose and Heat Resistance grade from Chang Chun, Taiwan and Sumidurez, Singapore.

- Resol (One Stage)

Resol (one stage) generate three-dimensional reticulated structure and water vapor (H2O). As a result, NO ammonia gas is generated.

- Example of Resol (One stage) phenolic molding compound are Sumikon PM9820 and PM9630 from Sumidurez, Singapore.

Phenolic molding material provided by Dowell Trading Co. Ltd.'s suppliers are manufactured by two major manufacturers - Chang Chun, Taiwan & Sumidurez, Singapore.

- Because of the excellent heat resistant and dimentional stability, phenolic moulding compound is still be one of the most competitive product at all time.

Characteristic

The characteristic of phenolic resin is to be determined by it's physical properties, thermal properties and electrical properties.

- For physical properties, several measurement have to be taken such as Impact Strength (ASTM D-256), Flexural Strength (ASTM D-790), Tensile strength (ASTM D-651), Compressive Strength (ASTM D-695), Molded Shrinkage (ASTM D-955).

For thermal properties, Heat resistance & Deflection Temp. (ASTM D-648), UL Flammability (UL-94) are taken.

- For electrical properties, Insulation Resistance (ASTM D-257), Dielectric Strength (ASTM D-149), Volume Resistivity (ASMT D-257), Arc Resistance (ASTM D-495) are taken.

For Reference only.Properties Unit Flexural strength MPa 69 ~ 150 Compressive Strength MPa 210 ~ 270 Tensile Strength MPa 48 ~ 90 Impact, Izod J/m 15 ~ 35 (Glass Filled) Deflection Temp. oC 180 ~ 260 UL CTI V ~ 300 Max. UL Flammability mm 94V-0 @ 0.40~6.40 Water absorption % 0.20 ~ 0.50 Molded Shrinkage % 0.40 ~ 1.10 Apparent density g/cm3 Avg. 0.6 Specific Gravity 1.40 ~ 1.82 Back to top